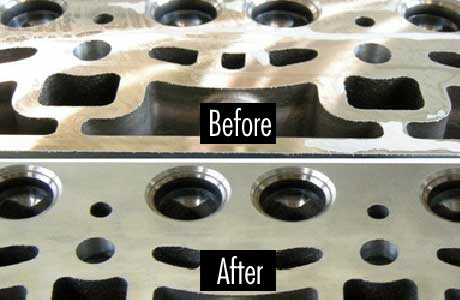

NamPower™ brush tools from Brush Research Manufacturing (BRM) are your complete choice for deburring, surface finishing, parts cleaning, and edge radiusing.

NamPower™ products are effective, reliable brushing tools that deliver a total finishing solution to a range of industries and applications. These high-performance professional grade brushes are made of the highest-quality materials and are ideal for manual and automated finishing machinery. For a complete deburring and finishing solution, choose NamPower™ abrasive disc brushes, composite wheels, or hex drive brushes.

Brush Research Manufacturing (BRM), makers of the Flex-Hone® and pioneers of plateau finishing, recommends NamPower™ brush products for extrusion, fine blanking, appliance manufacturing, and automotive parts.