The Flex-Hone® Tool

The Flex-Hone® Tool is the perfect solution to many of your finishing, deburring, and edge-bending needs. Available in a wide variety of sizes, abrasives, and grits to meet your specific requirements.

The Flex-Hone® Tool is the perfect solution to many of your finishing, deburring, and edge-bending needs. Available in a wide variety of sizes, abrasives, and grits to meet your specific requirements.

View Flex-Hone charts and sizes.

For Any Type And Size of Cylinder

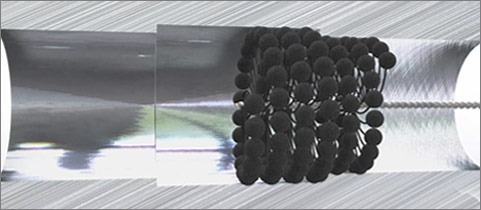

The Flex-Hone® Process (Super finishing) produces a controlled surface condition unobtainable by any other method. It involves finish, geometry and metallurgical structure. A high percentage plateau free of cut, torn and folded metal (with radiused ports).A resilient, flexible, cylinder honing tool with a soft cutting action. The abrasive (points) globules each have independent suspension that assures the Flex-Hone® to be self-centering, self aligning to the bore, and self-compensating for wear.

Specifically, it is a low-temperature abrading process that exposes the undisturbed base metal structure to produce a long wearing surface. It is a method of developing a surface on a metal part which is optically smooth and metallurgically free of any fragmented, amorphous or smeared metal from previous operations. It is accomplished at a low pressure where the "stones" float.

See and read the various booklets of actual tests covering almost every situation that will ensure a superior performance in situations depending on surface finish.

The particular type of Flex-Hone® crosshatch is extremely efficient in providing a multiplicity of oil grooves or valleys for oil retention as opposed to the often undirectional or uneven valleys common to the conventional type rigid hone. A crosshatch that usually remains as the cylinder wall has been wear-reduced by the FlexHone®.

Why use the Flex-Hone?

SURFACE FINISHINGThe Flex-Hone® Tool is available in a variety of abrasive types and grit selections to provide the optimum surface finish on any base material. The Flex-Hone®, also known as the cylinder ball hone, is commonly used to reduce Ra, Rk and Rpk values while maintaining Rvk and Vo volume for oil retention. Using the Flex- Hone® Tool for surface finishing allows the sizing tools to do their jobs quickly and accurately without fighting surface finish. The Flex-Hone® is also used in adhesive bonding applications where a rougher surface is desired for bonding integrity.

DEBURRING

Deburring of cross drilled holes is an expensive, time consuming operation. The Flex-Hone® Tool can be used to remove burrs from cross drilled holes leaving a clean, radiused intersection. Because of its unique construction, the Flex-Hone® can be used online in machine tool applications or offline as a secondary operation.

The cylinder honing tool is self-centering and self-aligning to the bore so elaborate, rigid set-ups are not required. It is advisable to use the tool in the main bore into which the cross holes break. Best results are obtained by rotating and stroking the flex hone a few strokes in a clockwise direction, removing the tool from the part, reversing the spindle and then rotating and stroking the tool in a counter clockwise direction for a few more strokes. This forward and reverse rotation creates a more symmetrical deburring pattern.

PLATEAU FINISHING

Brush Research pioneered the concept of a plateau finish and is a strong proponent of the benefits of a cross hatch, plateaued finish. The concept involves using flex hones to remove the peaks produced by prior machining operations to create a substantially flat or plateau finish. A plateau finish created by the elimination of peaks allows rings and seals to seat without damaging their edges. The cross hatch pattern will aid in lubrication control and retention, reduce seepage in hydraulic and pneumatic applications and promote longer seal life.

If Your Specifications Call For:

- A surface plateau of over 60%

- Producing an oil holding cross-hatch pattern

- Reducing Ra, Rpk and Rvk values

- Increased bearing area

- Lowered oil consumption

- Less blow-by

- Less friction

- Improved sealing surface

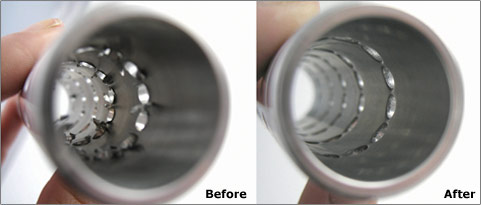

As received, rigid honed by factory rework section. "W" photo at 1000x. Cross-hatch has majority of cut in one direction. Smeared, torn, jagged and folded meal on surface. Smeared metal loosely attached to surface. Very peaky profile of finish. 40 to 50u" (1.02 to 1.27um) finish. Cylinder #B-1

After Flex-Hone.® 180 grit silicon carbide, "Y" photo at 1000x. Uniform crosss-hatch pattern. Clean open appearance with smeared, folded and torn metal removed. Excellent semiplateaued profile. Small dust particles visible on surface in "Y" photo. 20 to 25U" (.51 to .63 um) finish. Cylinder #B-1.