Flex-Hone® tools

Flex-Hone® for Cylinder Surface Finishing, Cross Hole Deburring, Deglazing, Edge Blending and Cleaning

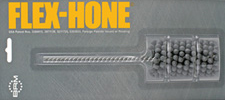

About Flex-Hone® tools

The Flex-Hone® tool was originally created by Brush Research Manufacturing to deglaze cylinder walls in automotive applications. Brush Research embraced the benefits of a plateau finish and pioneered the concept of plateau honing culminating in the introduction of the Flex-Hone tool in 1972. The Flex-Hone® tool produces an oil holding cross hatch pattern and a true plateau finish free of cut, torn and folded metal.

Any type or size of cylinder can benefit from the Flex-Hone®. These abrasive bead style brushes are produced in standard diameters from 4mm to 36”. Eight abrasive types are offered including silicon carbide, aluminum oxide, boron carbide and diamond allowing the tool to be tailored to finish any base material. A choice of 11 different grit selections are available for precise control of finish parameters. The elimination of peaks results in rapid ring seating, better oil control, reduced seepage in hydraulic and pneumatic applications and provides better seal performance and longer seal life. Successful applications include firearm chambers, shotgun barrels, musical instruments, combustion chambers, air compressors, pumps, valve bodies, valve guides, brake cylinders, wheel cylinders and the list goes on and on.

Flex-Hone® tools are also very effective for cross hole deburring, port radiusing and edge blending. Because of its unique construction, the Flex-Hone® is self-centering, self-aligning, and self-compensating for wear so it does not require an elaborate set-up or special training. Deburring with ball hones can be effectively automated and combined in the machining process to allow a complete cylinder finish in one operation or it can be employed as a secondary operation with equal results.

BRM continues to apply our years of experience and patented Flex-Hone® technology to solve difficult deburring and surface finishing problems. Our Flex-Hone® for Rotors now brings the same benefit to create the ideal surface finish on brake rotors, fly wheels and clutch plates. The tool reduces friction induced braking noises by producing a surface that lowers harmonic vibrations and creates a non-directional cross-hatch pattern. The Flex-Hone® for Rotors is more cost effective than abrasive pads and it is ideal for both new and re-turned rotors and flywheels.

The Brush Research BALLHONE® is BRM’s premium bulk abrasive finishing tool product. For more information on the BALLHONE® bulk product, please click here.

Flex-Hone® tools Are Great For:

- Engine and Brake Cylinders

- Valve Guides and Bodies

- Hydraulic and Pneumatic Cylinders

- Valve and Pump Housings

- Combustion Chambers

- Firearm Chambers

- Air Compressors

- Musical Instruments Repair

- ...and More!

Brush Research Mfg

- Punctual delivery with large in-stock selection

- One of the largest manufacturers of professional grade brushes and tools

- Helpful technical advisors ensure you get exactly the right tools you need

- International Distribution

- ...and more!

Manufacturing Flex-Hone® tools

Brush Research manufactures the Flex-Hone® tool under the most rigid quality standards.

As an ISO 9001:2015 certified company, BRM is committed to making quality Flex-Hone® tools products.

100% of our Flex-Hone® tools are made in the USA. We offer application assistance and a full test lab for your most difficult projects.

Members Of